★Breaking News★ Received the Grand Prize by the Judging Committee of the 14th "Most Cherished Company in Japan" Awards.

Latest Information

★Breaking News★ Received the Grand Prize by the Judging Committee of the 14th "Most Cherished Company in Japan" Awards.

Latest Information

Topics

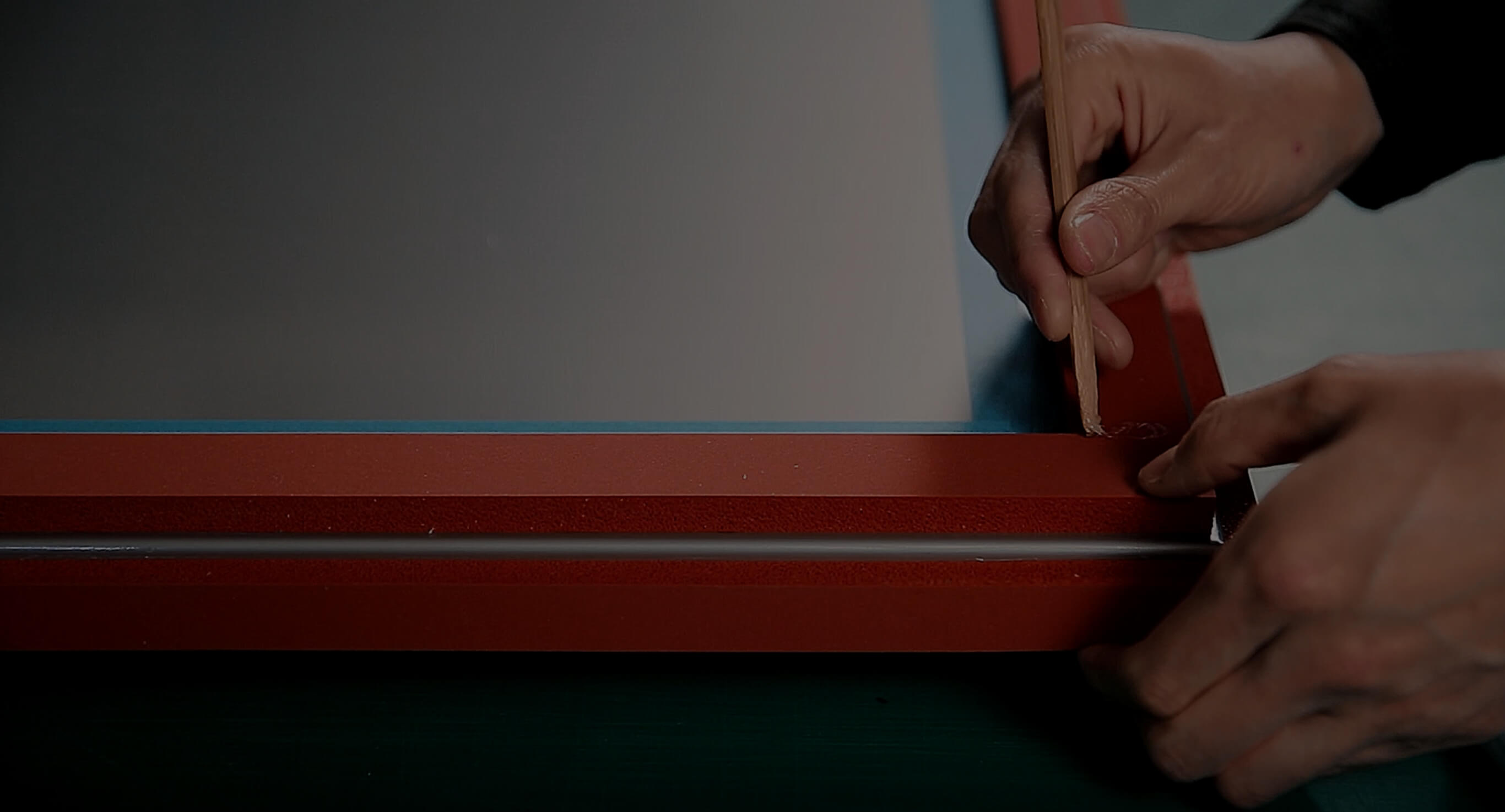

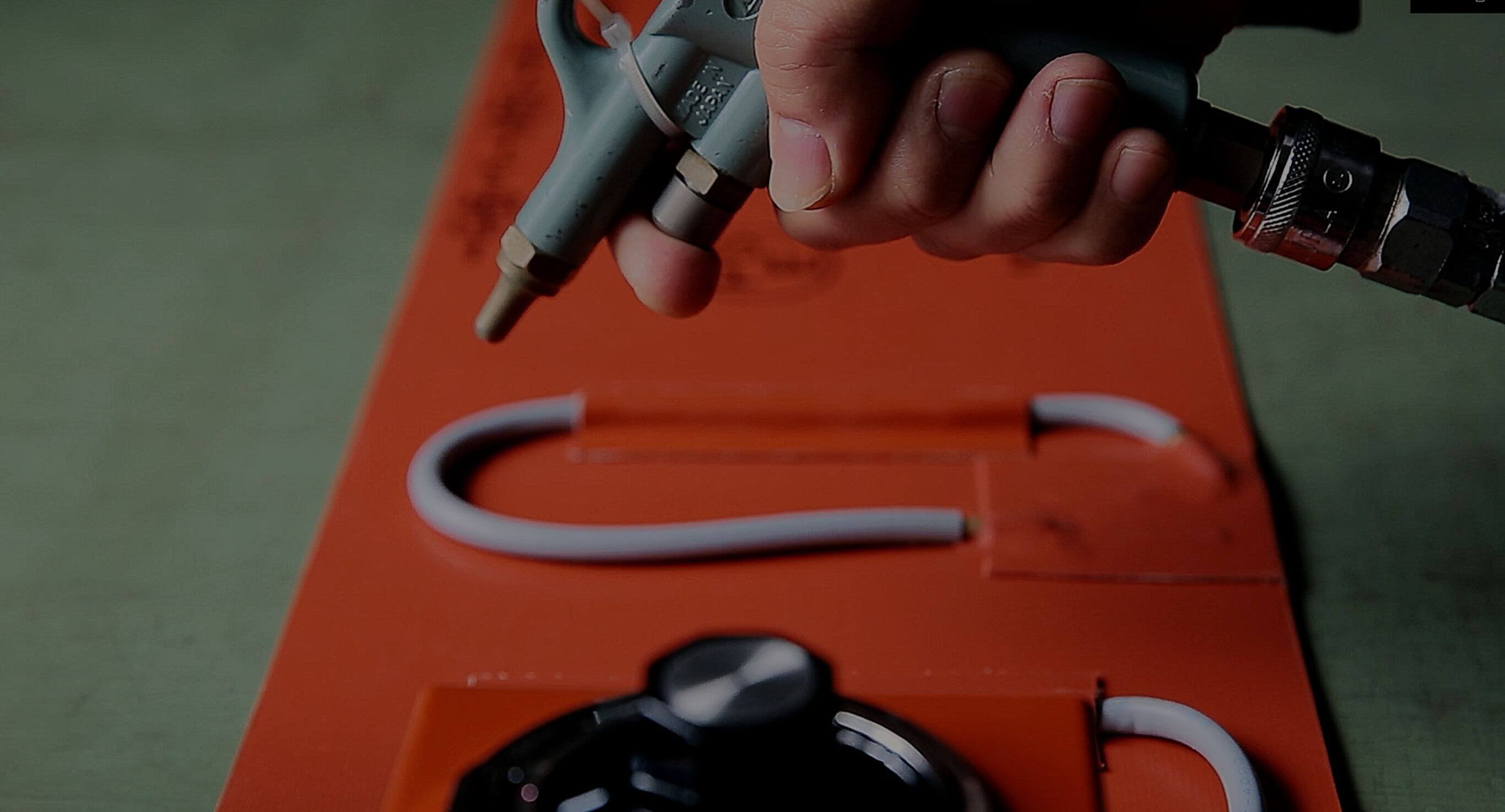

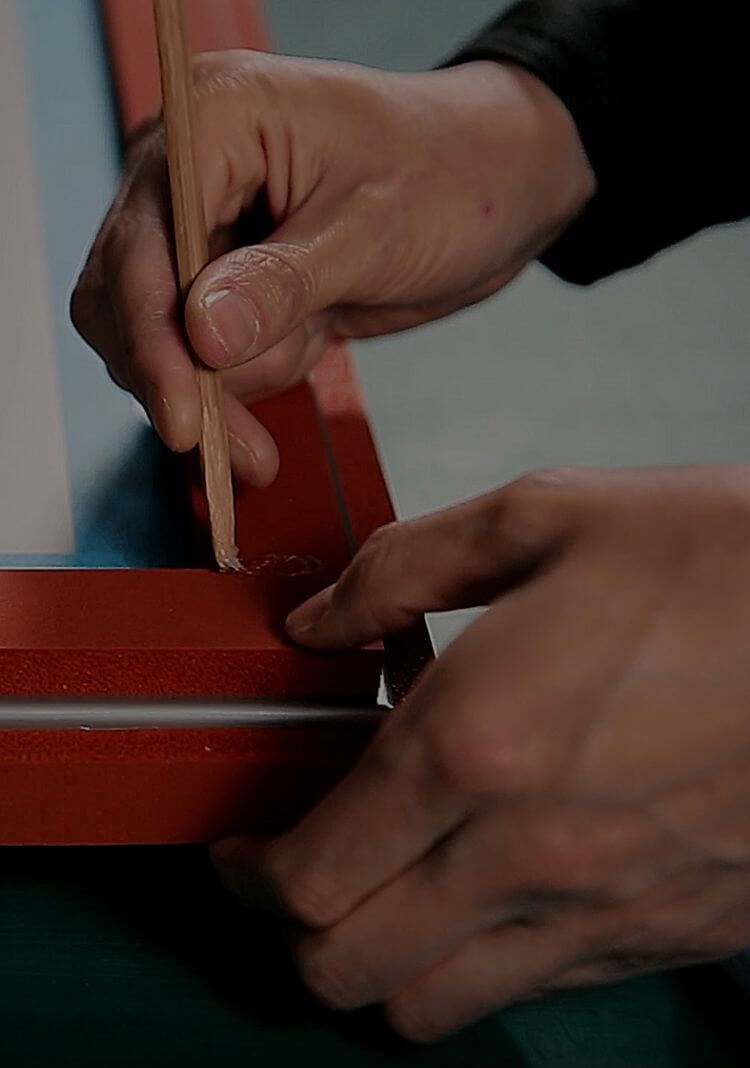

We care about things,

we care about people.

We want to warm things and people through

the manufacture of heaters.

Made in Japan

Products

-

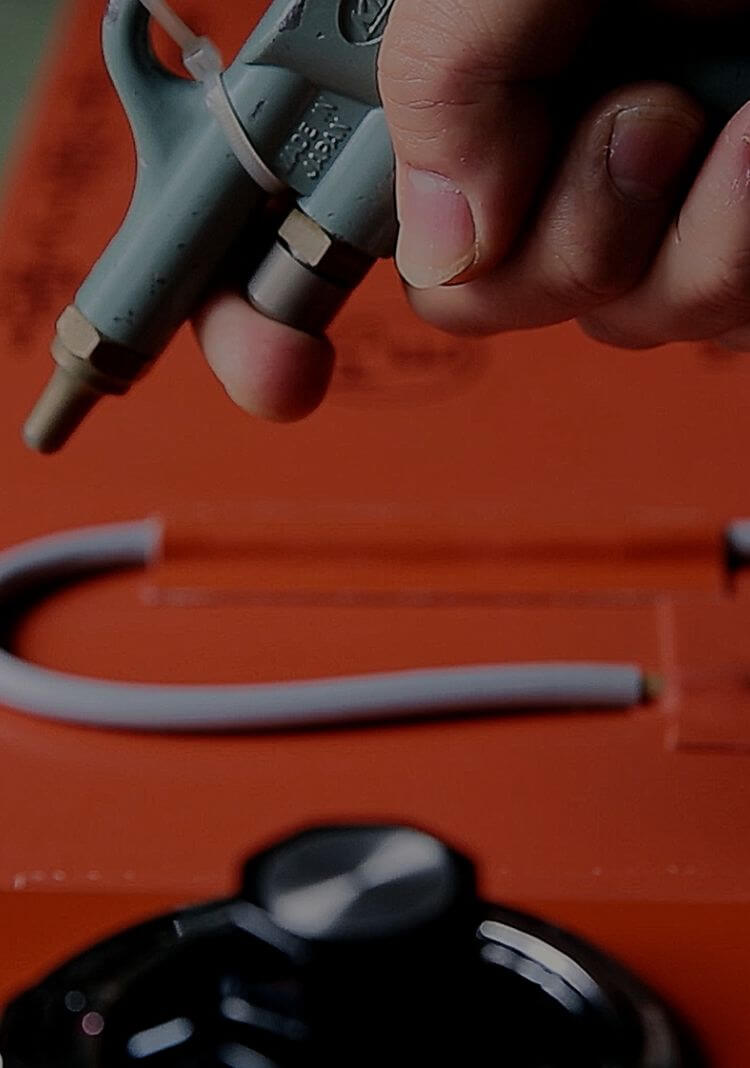

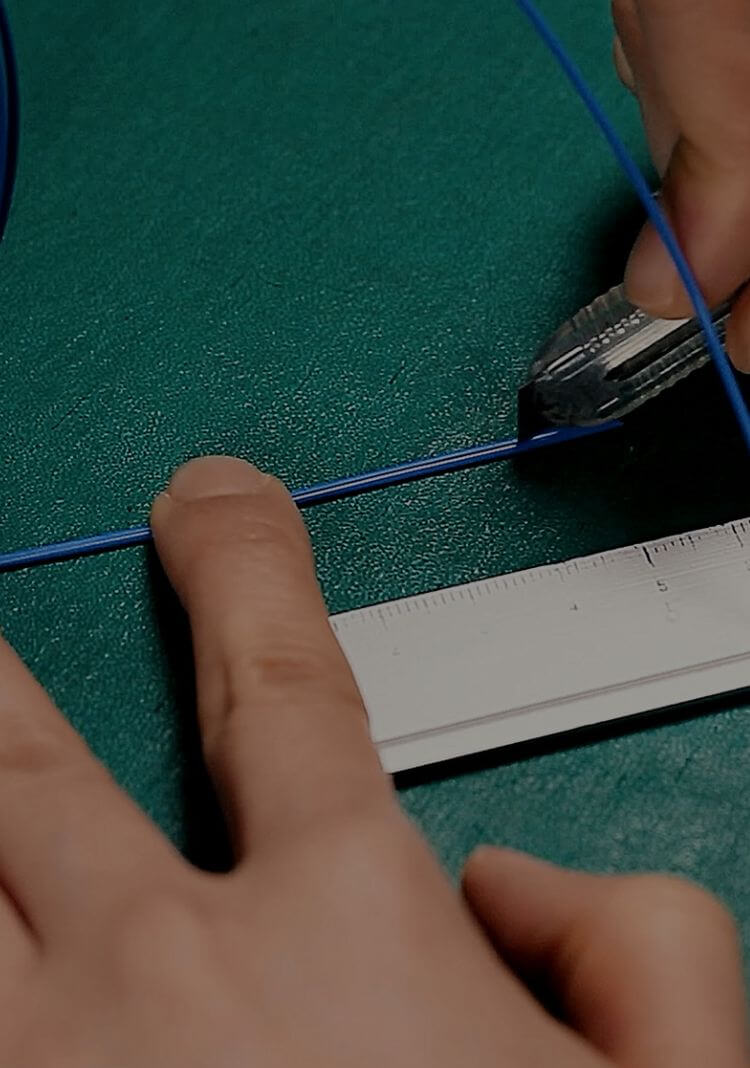

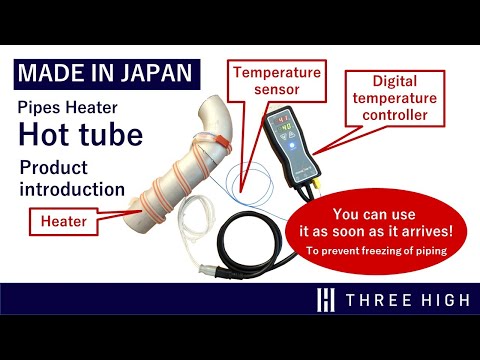

Various heaters

Mass production, as well as producing single-products are possible. Our line-up of many heaters, up to a maximum of 700°C

Click to see various heaters -

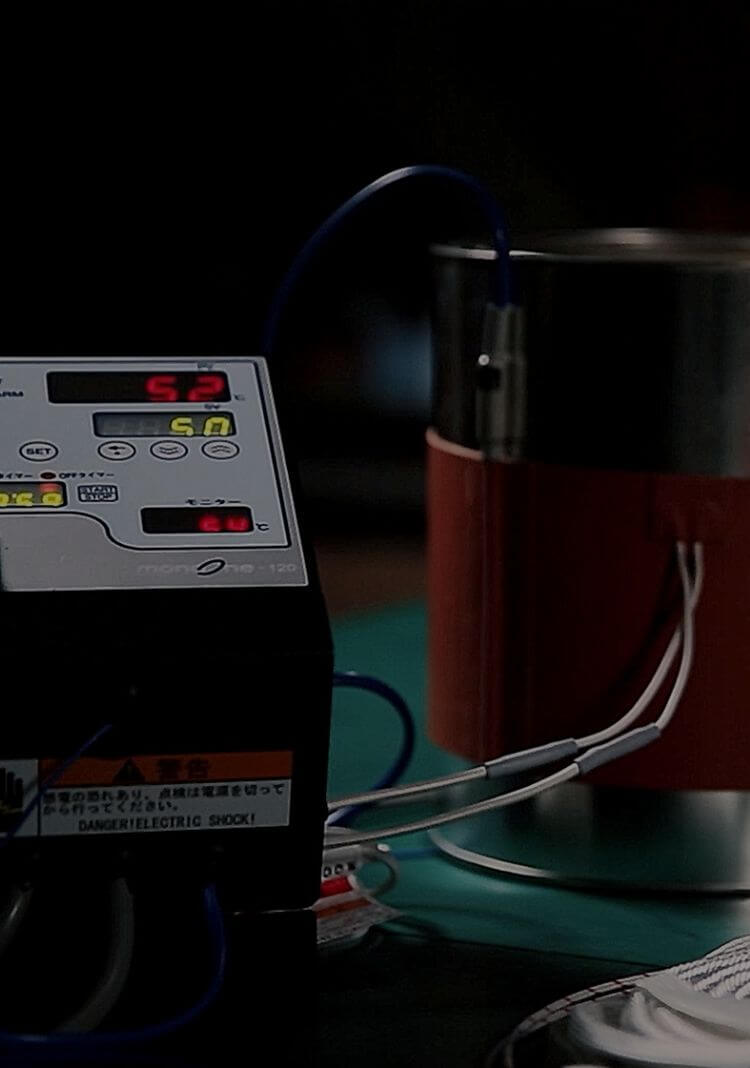

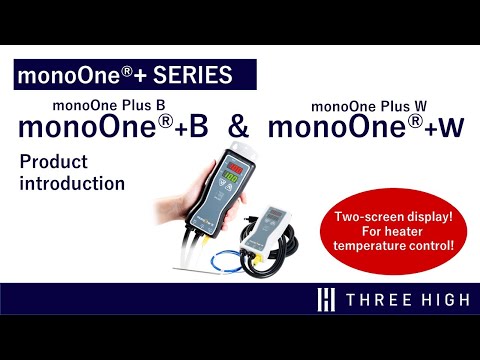

Temperature controllers

Our digital temperature controller, MonoOne has three series available from startars to professionals.

Click to see temperature controllers -

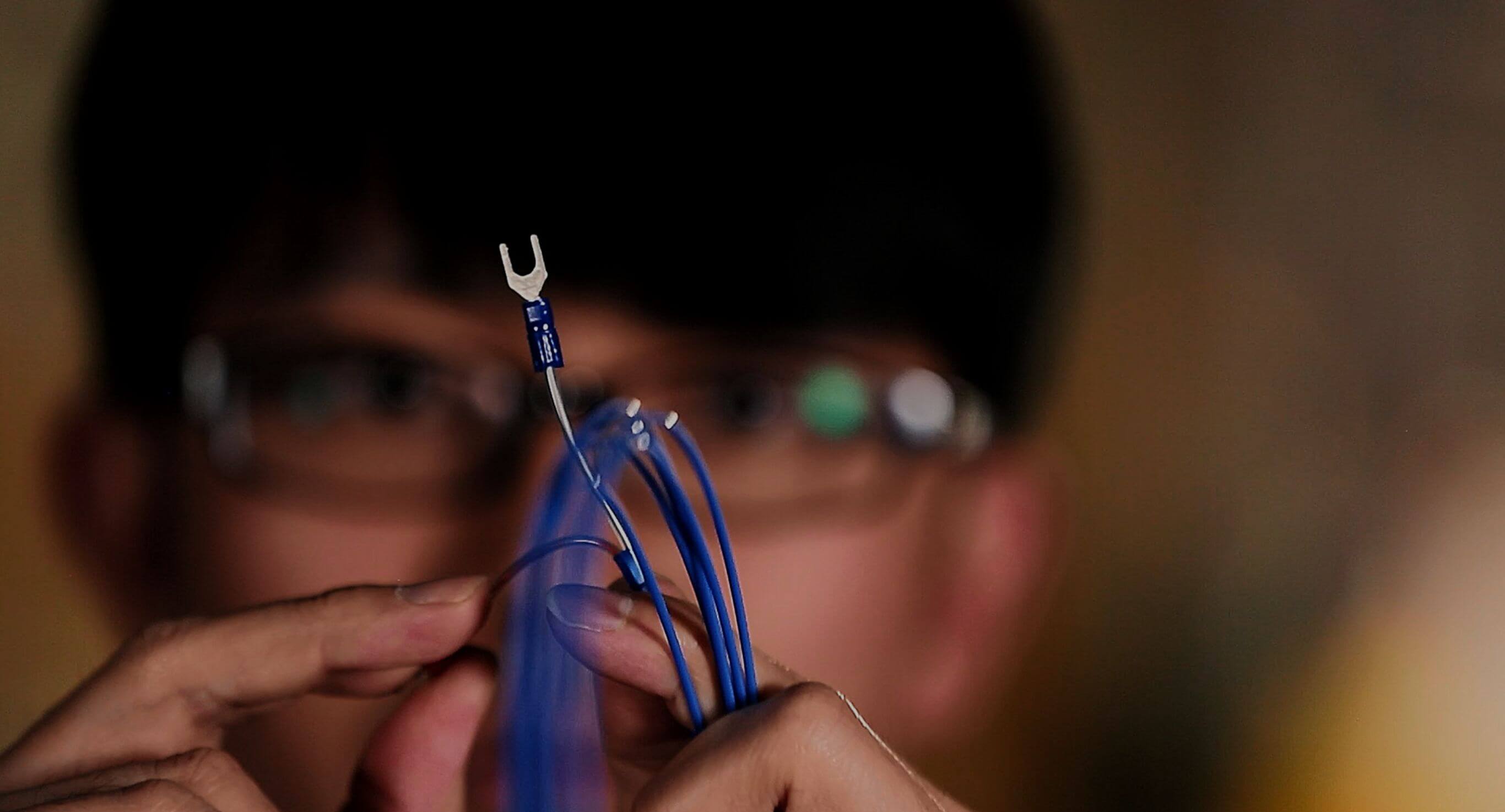

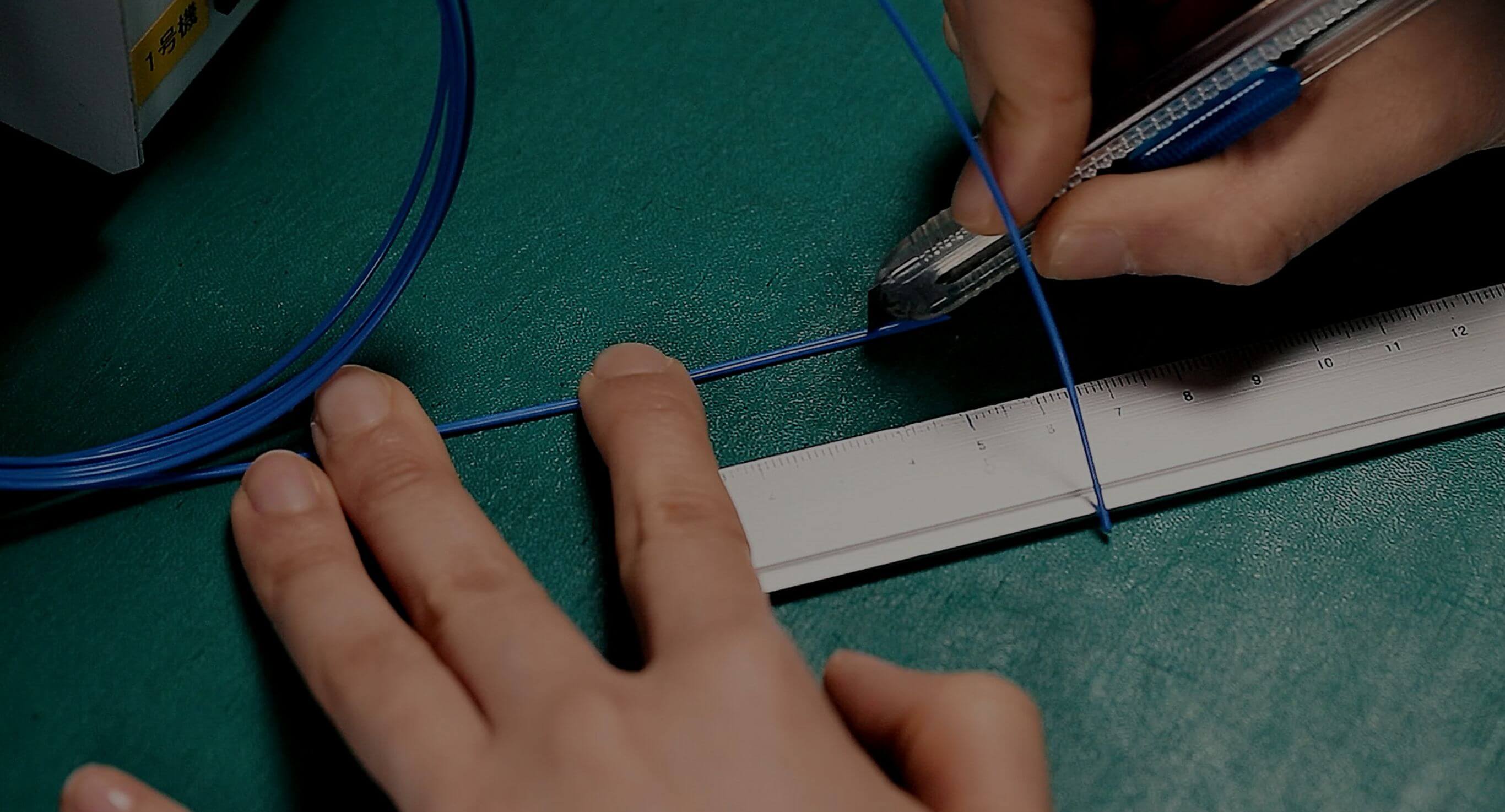

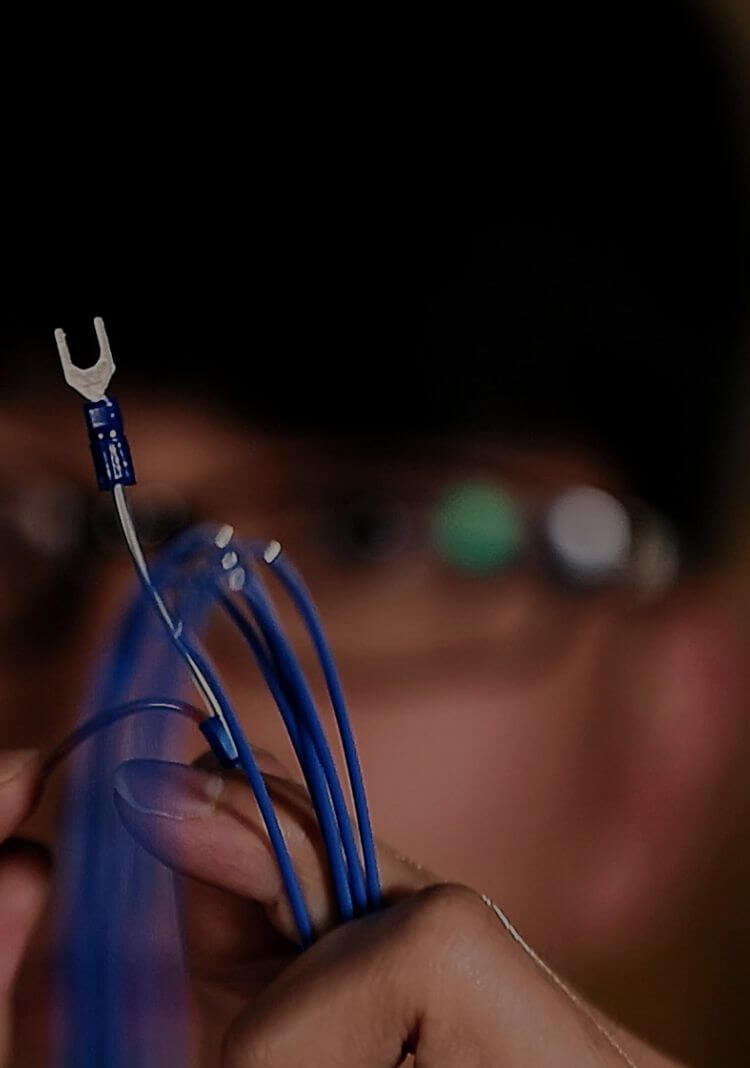

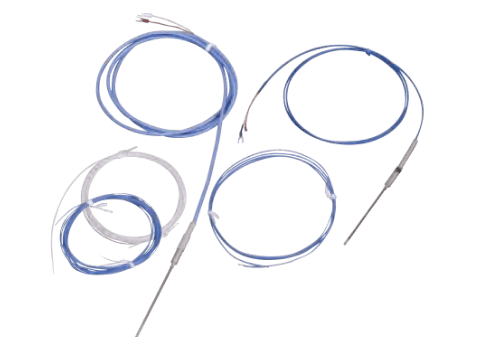

Temperature sensors

Various types of thermocouples (Type K) and platinum resistance thermometers (Pt100Ω)

Click to see temperature sensors -

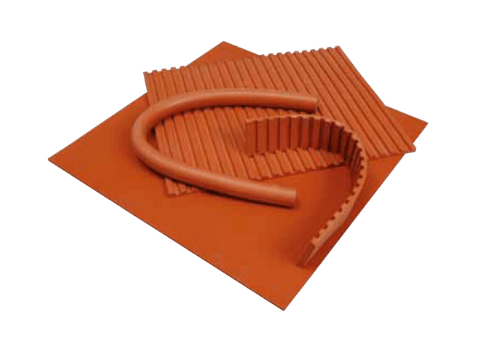

Silicone sponge

Excellent in insulation and heat retention! Various types of sheets, tubes, and square strips.

Click to see silicone sponges

Company

We bring warmth

We want to deliver warmth to the factories, to the community, to the town, and to the world.

We want to make our employees, our families, our customers, and our community feel warm with us.

It is our goal to spread warmth through smiles and laughter.

That is why we are manufacturing idustrial heaters and nurturing manufacturers and carriers all over the world.

This is what we do.

HEART MIND

LATEST NEWS

★Breaking News★ Received the Grand Prize by the Judging Committee of the 14th "Most Cherished Company in Japan" Awards.

Latest Information

★Breaking News★ Received the Grand Prize by the Judging Committee of the 14th "Most Cherished Company in Japan" Awards.

Latest Information

A new intern has joined from Netherlands!

A new intern has joined from Netherlands!  Exhibition Information

Exhibition Information  【Announcement】 On January 21st, ThreeHigh will be featured on BS TV Tokyo's "Wings of Growth."

PR/Media

【Announcement】 On January 21st, ThreeHigh will be featured on BS TV Tokyo's "Wings of Growth."

PR/Media

METALEX 2023 - Machine Tools & Metalworking Exhibition in Bangkok, Thailand

METALEX 2023 - Machine Tools & Metalworking Exhibition in Bangkok, Thailand